In modern industries and complex electronic application

environments, the requirements for cable performance are becoming

increasingly stringent. Especially in high - temperature working

conditions, cables need to possess stable and reliable

characteristics. High - temperature cables with glassfiber braiding

play a significant role in numerous fields, relying on their unique

structures and excellent properties.

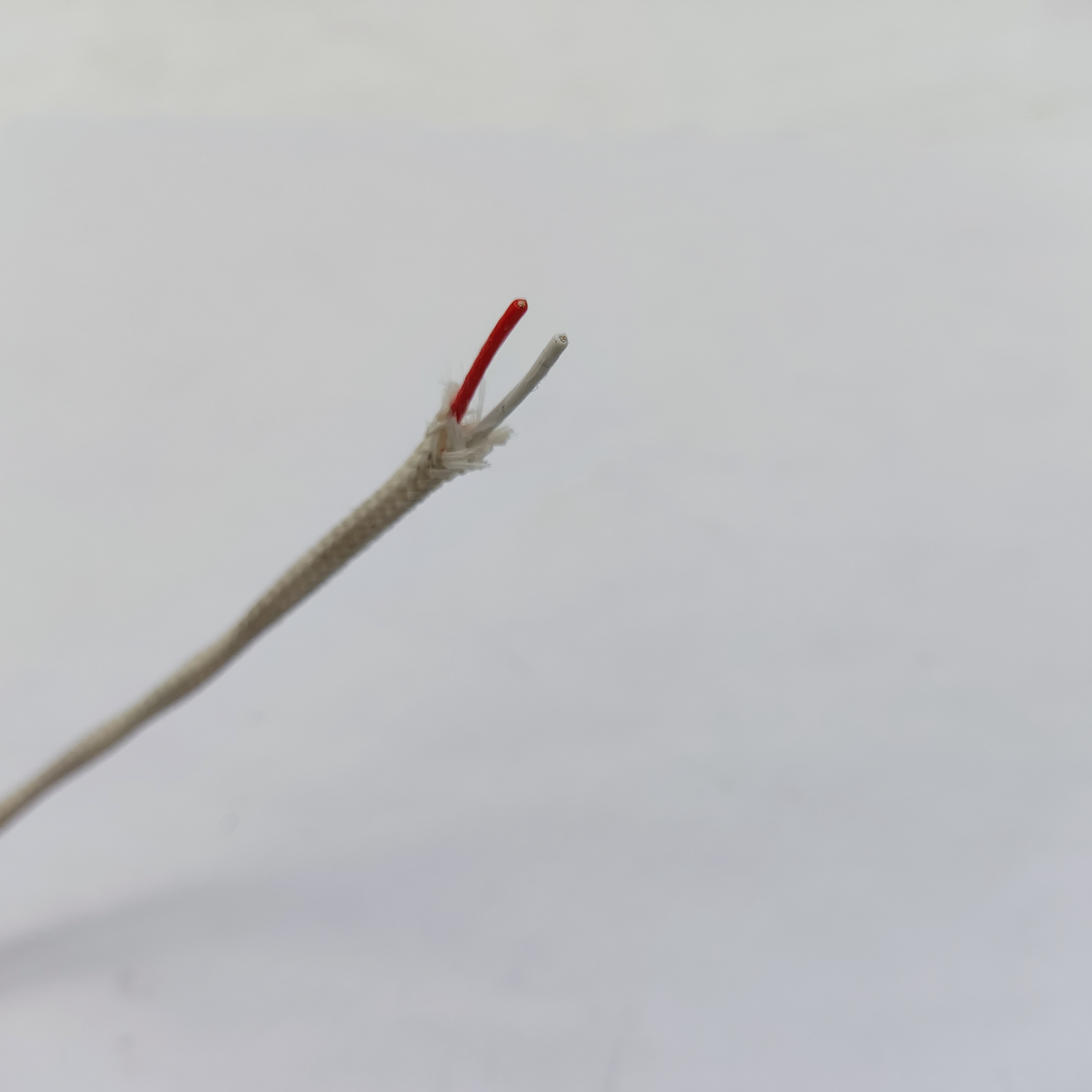

I. Structural Features

1. Conductor: Tinned copper is adopted as the conductor material.

It has excellent electrical conductivity, which can effectively

reduce the resistance loss during signal transmission and ensure

stable current transfer. The tin - plating treatment enhances the

oxidation resistance of the copper conductor, extending the service

life of the cable and enabling it to maintain good electrical

performance in various complex environments.

2. Structural Details: The specific structure of the conductor is

7/0.12, which means it is composed of 7 fine copper wires with a

diameter of 0.12mm twisted together. This multi - strand twisted

structure endows the cable with good flexibility, making it easy to

bend and install during wiring, and adapting to various complex

wiring environments.

3. Insulation Layer: The insulation material is FEP (fluorinated

ethylene propylene). FEP has outstanding insulating properties,

which can effectively isolate the electrical connections between

conductors and between the conductor and the outside world,

preventing signal interference and short - circuit phenomena.

Meanwhile, it can maintain stable physical and chemical properties

in high - temperature environments, ensuring the insulation

reliability of the cable during high - temperature operation.

4. Number of Cores: This cable has a 2 - core structure, which is

suitable for application scenarios that require the simultaneous

transmission of multiple signals or power, such as the combination

of power lines and signal lines in some small - scale electronic

devices.

5. Jacket: The outermost layer is a glassfiber braided jacket,

which is a major feature of this cable. Glassfiber has

characteristics such as high strength, high - temperature

resistance, and corrosion resistance. The braided structure not

only provides mechanical protection for the cable, preventing it

from being damaged by external forces, but also remains stable in

high - temperature environments, ensuring that the cable can

operate normally within a wide temperature range from - 40°C to +

200°C.

II. Electrical Performance

1. Rated Voltage: The rated voltage of this cable is 60V, making it

suitable for some low - voltage electrical equipment and electronic

devices. It can stably transmit power and signals within this

voltage range, meeting the normal operation requirements of these

devices.

2. Rated Temperature: Its operating temperature range is from -

40°C to + 200°C, demonstrating excellent high - temperature and low

- temperature resistance. Whether beside high - temperature

industrial furnaces or in cold outdoor environments, it can

maintain good electrical and mechanical properties, ensuring the

reliable operation of equipment.

III. Application Fields

1. Industrial Automation: In automated production lines in high -

temperature environments, it is used to connect various sensors,

actuators, and controllers to ensure stable signal transmission and

the normal operation of equipment. For example, in the high -

temperature rolling workshops of steel mills, the cable needs to

work in an environment with high - temperature radiation and

vibration. The glassfiber braided jacket of this cable can

effectively resist high - temperature and mechanical damage,

ensuring the stable and reliable automated control of the

production line.

2. Electronic Equipment Manufacturing: During the production of

some electronic equipment with high - temperature requirements,

such as high - temperature testing equipment and electronic welding

equipment, this cable can be used as an internal power line or

signal line. Due to its high - temperature resistance, it can

ensure the stability of electrical connections in equipment during

long - term high - temperature operation.

3. Aerospace: In the aerospace field, some equipment needs to

operate in extreme temperature environments. The high - temperature

and low - temperature resistance as well as good flexibility of

this cable make it suitable for sensor wiring in aircraft engine

compartments, internal connections of satellite electronic

equipment, etc., ensuring the accuracy and reliability of signal

transmission under harsh environmental conditions.

High - temperature cables with glassfiber braiding, with their unique structures and

excellent performances, provide reliable connection solutions for

numerous high - temperature applications. With the continuous

development of technology, their application prospects will be even

broader.